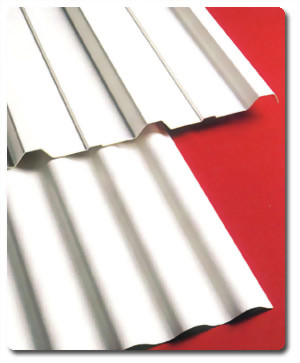

WMP Corrugated Sheet

The

general roof and wall materials such as steel, aluminum and asbestos all have

serious deficiencies. The deficiencies are unsatisfactory weather resistance,

poor durability, corrosion, rust and can't stand rain and wind. They cause

losses and wastes to the people.

THE PHYSICAL PROPERTIES

| Specific gravity | 1.4~1.42 g/cm3 |

| Tensile strength | 600~800 kg/cm2 |

| Module of elasticity | 2.8~3.2 kg/cm2x10 |

| Flexural strength | 800~1000 kg/cm2 |

| Coefficient of thermal conductivity | 0.08~0.10 kcal/m.h.oC |

| Electricity Resistance | 1015 Ω /cm |

| Flammability | Self Extinguishing |

| HDT 264 psi | 70~80oC |

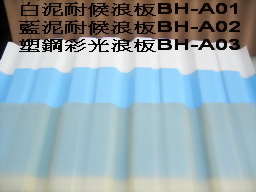

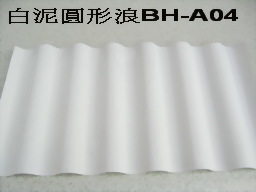

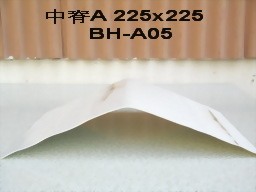

TYPES AND SPECIFICATIONS

|

(1)(m/m)

Thickness |

(ft)

Length |

(inch)

Width |

(2)(m/m)

Depth |

(3)(m/m)

Pitch |

NO. of Corruggations

|

||

|

Small Wave

.gif) |

1.0

1.3 1.5 2.0 |

6~19

|

30

|

15

|

63

|

125

|

||

|

Grand Wave

|

1.0

1.3 1.5 2.0 2.5 |

6~19

|

30

|

18

|

76

|

10

|

||

|

Channel

|

1.3

1.5 2.0 2.5 |

6~19

|

810 m/m

|

27

|

185

|

5

|

||

|

Channel

|

1.3

1.5 2.0 2.5 |

6~19

|

840 m/m

|

27

|

265

|

4

|

-

Weather resistance, aging proof- WMP weather resistant plastic is produced from special materials. The raw material contains ultra-violate resistant absorbing agent and eliminates the PVC being decomposed by ultrviolate light. For general plastic products, one of the PVC ingredient can easily turn into hydroxide by the sun light after high temperature fabrication or long term exposed to the sun. But the white mud plastic can absorb this newly reacted hydroxide and stabilize to maintain the aging resistant function.

- Excellent heat insulation- The coefficient of heat conductivity of WMP corrugated sheet is really now. The bright colors can also reflect sun light and will not absorb the heat. It will reduce interior temperature by 3oC~5oC.

- Excellent chemical resistance- WMP weather resistance reinforced plastic corrugated sheet can resist most of organic solvents, salts, acids and alkalis. It is suitable to be used at areas with strong erosion.

- Safety- Non flammable, non combustion, the electric insulation is as high as 1015-cm. It is a excellent electric insulator and will not conduct current when thunder strikes. There is not dust. will not cause cancer and promises human's health.

- Resilient and strong- Impact resistant, pressure resistant, shake resistant and bending resistant. WMP wather resistance reinforced plastic corrugated sheet has proceeded with impact test. A 1kg eggplantshaped heavy weight was dropped from 300cm height into the corrugated sheet and the sheet was not cracked (CNS 3114 test standard is to drop a 1kg eggplant-shaped heavy weight from 120cm height. The test is approved if the sheet was not cracked).

- Fine out-looks- The material of WMP weather resistance corrugated sheet is smooth and fine, with bright colors and will easily coordinate with building out-looks.

- Light permeability- VMP corrugated sheet has 1/100 light permeability. It is bright without heat. The inner layer is bright and smoot with good reflectivity which will increase interior brightness, hence achieve energy saving.

-

Light material- The weight ratio is 1.4~1.45 which is lighter than asbestos and iron sheets. A sheet of equal length and width WMP corrugated sheet only weights 1/8 of asbestos. Therefore, reduces the frame load.

|

Drug |

Acid |

Alkali |

Organic

Solvent |

Acidulating agent |

|||||||||

|

Sulfuric Acid |

Hydrochloric Acid |

Nitric Acid |

Acetic Acid |

SODA (Sodium Carbonate) |

Formalin |

Carbon Tetracholride |

Acetone |

Ethyl Acetate |

Vinyl |

Gasoline |

odium Hypochlorite |

||

| 60% | 35% | 70% | 90% | 5% | 15% | 40% | 100% | 100% | 100% | 100% | 100% | ||

|

Result |

|

|

|

|

|

X |

|

|

X | X |

|

|

|

|

|

|

|

X Unusable |

APPLICATIONS

Modern manufacturing plants, chemical plants and treatment plants, sports stadium. Shops, warehouese, tourism facilities, marine products/ agricultural industry, boats and ships, general house peripheral facilities and various shades.